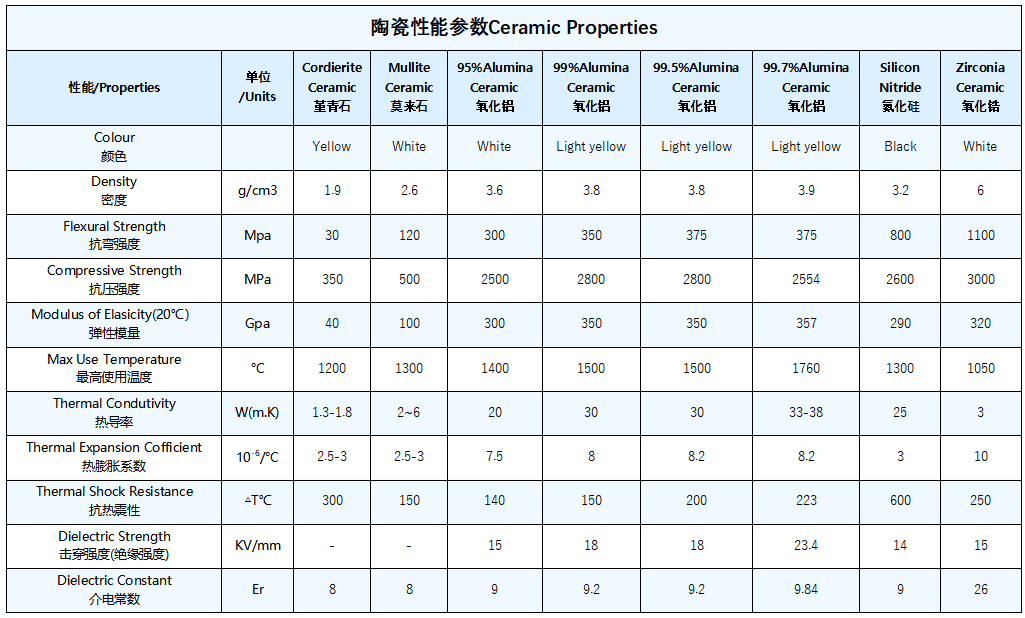

People usually call the ceramics with 75% dry Al2O3 content as high alumina ceramics. Alumina ceramic is one of the most widely used structural ceramics. It is more economical and practical to use 95% alumina ceramic in general situations. Only 99%~99.9% alumina ceramic is used for occasions with high performance requirements.

Внедрение продукции

Alumina, or aluminum oxide, with a molecular weight of 102, is the major source of aluminum in nature. Alumina has very high melting point, which is 2,072 °C and it is extremely hard. Alumina ceramic is the common technical ceramic material and a relatively traditional material. High purity alumina ceramics as a fine ceramic material is widely used in a lot of industries. This material has superb performances in electrical insulation, high chemical resistance and low thermal expansion. Alumina tubes are used for industrial furnace and thermal couple protector. High purity alumina materials are excellent for making parts for CVD, ion implants, photolithography, and semiconductor parts. In traditional industries, alumina ceramics are ideal for products such as injector tubes, gas nozzles and insulators. Compared with metals, alumina ceramic material is extremely hard, making it an ideal material for abrasive, grinding media. Alumina mortars and pestles are widely used in laboratories for grinding hard materials.

Alumina is a well-known and commonly used precision ceramic material. It has the same sintered crystals as sapphire and ruby. For decades, it was once used in electrical components because of its high electrical insulation. It is widely used in mechanical parts because of its high strength, high corrosion resistance and high wear resistance.

Main Features:

1. High hardness

2. High heat resistance

3. Good wear resistance

4. High electrical resistivity

5. High corrosion resistance

People usually call the ceramics with 75% dry Al2O3 content as high alumina ceramics. Alumina ceramic is one of the most widely used structural ceramics. It is more economical and practical to use 95% alumina ceramic in general situations. Only 99%~99.9% alumina ceramic is used for occasions with high performance requirements.

Because it has excellent electrical performance at high frequency, its dielectric loss is small, its volume negative rate is large, its strength is high, its hardness is large, its linear expansion coefficient is small, and its wear resistance and heat resistance are also good.

95% alumina ceramics have good thermal shock resistance, and can withstand the test of high temperature and rapid cooling without damage.

Запросите предложение сегодня

Будь то запрос продукта или техническая помощь, пожалуйста, отправьте сообщение здесь, наша команда ответит в течение 8 часов.

Предмет : Ceramic Substrate

Если у вас есть какие-либо вопросы или вам нужна помощь, не стесняйтесь обращаться к нашей команде.

Телефон

+86 183 5248 9056

Электронная почта

claire@shengdaceramic.comРасположение

Деревня Q Ian Luo, город Dingshu, город типа Y I, провинция Цзянсу, Китай

Добро пожаловать, чтобы подписаться на нашу электронную почту!

Copyright © Yixing Shengda Refractory Ceramic Co., Ltd. Все права защищены | Карта сайта | Техническая поддержка